The Marvels of Modern Aviation: The Incredible Advances in Aluminum Aircraft Design

- thepipingmart9

- Apr 22, 2023

- 3 min read

Updated: Apr 27, 2023

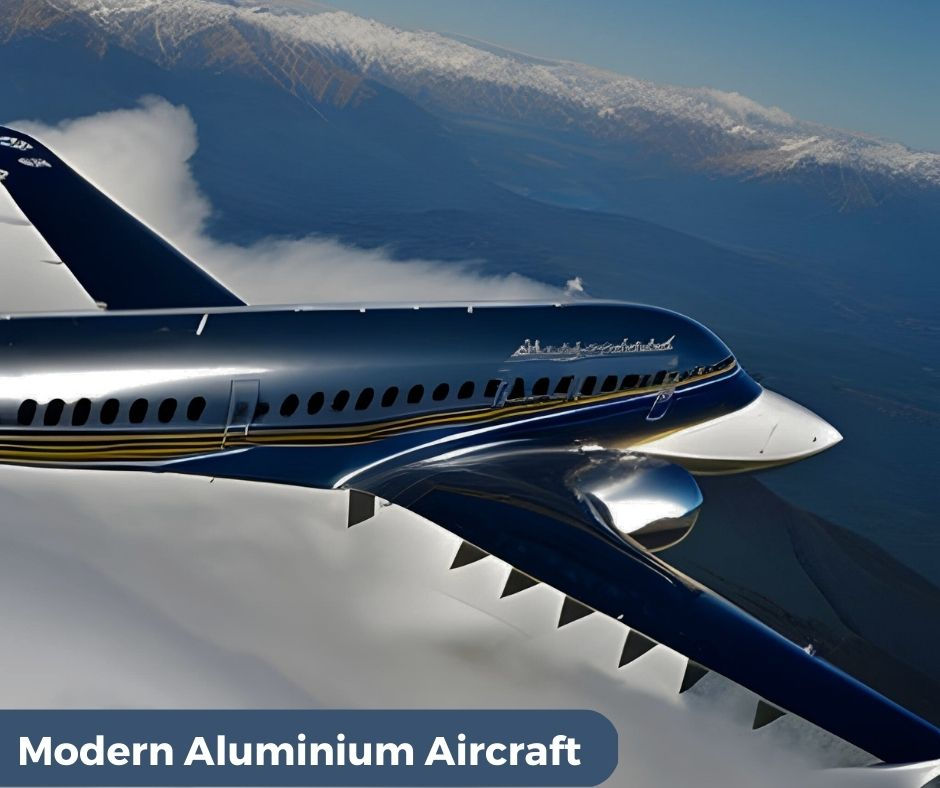

From the earliest days of aviation, the design and construction of airplanes have been constantly evolving. One of the most significant materials used in airplane construction is aluminum, known for its strength, durability, and lightweight properties. Over the years, advances in aluminum aircraft design have given rise to new generations of planes that push the limits of speed, efficiency, and safety. In this blog, we’ll explore the incredible innovations and advancements in aluminum aircraft design that make modern aviation possible. For information About High quality Aluminum Sheet and Plates Visit this Site.

The use of aluminum in aircraft construction can be traced back to the early days of aviation in the 1920s and 30s. However, it wasn’t until the development of high-strength, corrosion-resistant alloys in the 1940s that aluminum became the material of choice for commercial airplane design. Today, virtually all commercial airplanes rely on aluminum for structural components, including the fuselage, wings, and engines. The advantages of using aluminum in airplane construction are many. Apart from its lightweight, aluminum is also incredibly strong, able to withstand extreme stresses and strains while maintaining its form. Additionally, the material's corrosion resistance ensures longevity, making it ideal for the harsh environments of aviation.

Modern aerospace engineers have taken advantage of advances in aluminum technology to design aircraft that are more efficient and more durable than ever before. New aluminum alloys 7075 series are much stronger than previous generations, allowing designers to reduce the weight of aircraft while maintaining structural integrity. Advances in manufacturing technology have also allowed for the creation of complex, lightweight structural components like wing skins and fuselage panels that further reduce weight while enhancing overall performance.

Aluminum isn’t just used for structural components, either. The metal is also commonly used in the design of aircraft engines, including fan blades, compressor blades, and other critical components. High-strength aluminum alloys like 2024 are often used in engine components due to their excellent fatigue resistance and ability to withstand extreme temperatures. Other aluminum alloys, like 6061 and 7075, are used in the design of landing gear and other non-structural components.

But aluminum isn’t just making planes more efficient and durable—it’s also making them safer. Advances in aluminum technology have allowed for the design of enhanced safety features like aluminum honeycomb structures that provide excellent crash resistance while reducing weight. Additionally, aluminum's excellent durability and corrosion resistance reduce the risk of component failure, ensuring the safety and reliability of modern aircraft.

Benefits of using aluminum in aircraft

Aluminum is frequently used in aircraft construction due to its light weight and high strength-to-weight ratio. This makes it possible to produce lightweight, yet strong and durable aircraft structures with aluminum. Additionally, aluminum alloys are corrosion resistant which helps protect against rust and oxidation in the presence of moisture or heat. The use of aluminum in aircraft also reduces fuel costs since lighter materials require less energy to lift into the air.

Conclusion:

Today's aluminum aircraft are marvels of engineering, representing the culmination of decades of design and technological innovation. With advances in aluminum technology and design, aerospace engineers can push the boundaries of what's possible, creating new, efficient, and safe ways to travel the world. From the strength of its structural components to its critical role in modern engine design, aluminum is an essential element in modern aviation that will continue to shape the industry for years to come.

Comments